Biomass as a source of raw materials

New process for obtaining alkanes from bio-oil

For the protection of the environment, and because of the limited amount of fossil fuels available, renewable resources, such as specially cultivated plants, wood scraps, and other plant waste, are becoming the focus of considerable attention. Processes such as pyrolysis or liquefaction allow the conversion of biomass into bio-oil, a highly promising renewable source of energy. A team of German and Chinese scientists led by Johannes A. Lercher at the Technical University of Munich has now developed a new catalytic process to convert components of bio-oil directly into alkanes and methanol. As reported in the journal Angewandte Chemie, the process is based on a "one-pot" reaction catalyzed by a precious metal on a carbon support combined with an inorganic acid.

Bio-oil is an aqueous, acidic, highly oxidized mixture. However, its high oxygen content and instability turn out to have a negative impact: bio-oil cannot be used directly as a liquid fuel. It would, however, be highly interesting as a source of basic raw materials if it were possible to convert it to alkanes. Alkanes, which are also commonly called paraffins, are saturated hydrocarbons; they are among the most important raw materials for chemical industry, and in particular as starting materials for the production of plastics. Furthermore, they are among the primary fuels in the world's economy.

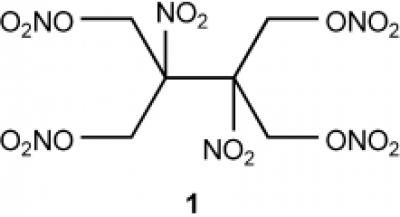

Bio-oil contains a phenolic fraction consisting of compounds with the main framework being an aromatic ring made of six carbon atoms with some hydroxy (-OH) groups attached. With the new process, the phenolic components of bio-oil can be converted with high selectivity to cycloalkanes (ring-shaped alkanes) and methanol. The researchers were able to demonstrate this with various model substances. As catalyst, they used palladium metal on a carbon support, with phosphoric acid as the proton source for the reaction.

The reaction is a "one-pot" reaction, meaning a one-step reaction whose partial reactions (hydrogenation, hydrolysis, and dehydration) occur in the same reactor, with no intermediate work-up. The secret is in the catalyst, which works on all of these different reactions. The end result is a mixture of various alkanes that separates into a second phase, making it easy to separate from the aqueous bio-oil phase. The new process is a practical approach for the direct use of bio-oil for the production of alkanes.

Original publication: Johannes A. Lercher et al.; "Highly Selective Catalytic Conversion of Phenolic Bio-Oil to Alkanes"; Angewandte Chemie International Edition 2009, 48, No. 22, 4047-4050

Most read news

Topics

Organizations

Other news from the department research and development

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.