Spying on Plastic Production

On-line Monitoring of Particle Growth in Catalytic Polyethylene Slurries

Real-time monitoring of high-density polyethylene (HDPE) production is now possible. In an article in the journal Macromolecular Reaction Engineering, Professor Rolf Mülhaupt and his student Rainer Xalter of Albert-Ludwigs University in Freiburg, Germany, describe how they use a combination of laser reflectance measurements and video monitoring to follow the polymerization of ethylene in slurries in standard commercial-scale reactors. They watch the slurries as the plastics grow under different conditions, and are able to use the results to explain variations in efficiency and product range.

HDPE, the most common form of polyethylene, is produced in catalytic slurries. Current methods for monitoring these types of reactions have involved off-line monitoring or the use of special cells without stirring. Stirring is necessary in commercial polyethylene production, but it plays havoc with standard particle monitoring techniques, and it is the particles that must be under constant surveillance if the reaction is to be followed closely.

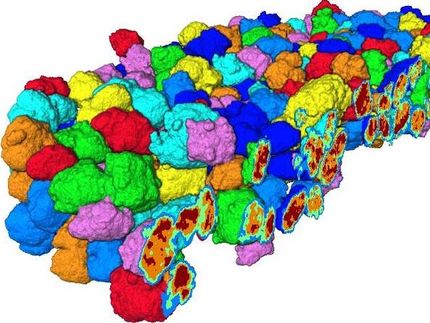

In slurries, polyolefins are made using supported Ziegler and metallocene catalysts, which assist the small olefin, or alkene, molecules to break bonds and join together into polymers. The polymer (or plastic) particles grow on a macroscopic scale as, simultaneously, the catalyst breaks up. According to the authors, “This very complex interplay of polymer particle growth and catalyst particle fragmentation governs polymerization kinetics and as well as polymer particle morphologies and bulk densities.” In gas-phase reactions, optical microscopy has been combined with video to effectively monitor particle growth in-line. Rainer and Mülhaupt have taken this basic idea and developed it to a new level to enable it be applied to stirred slurries, which are far more complex environments to observe.

The new technique involves using a LasentecTM “Particle Vision and Measurement” (PVM) probe developed by Mettler-Toledo GmbH, which, the authors explain, “makes video microscopic images of moving particles technically feasible via CCD camera-mediated imaging using a pulsed light source”, combined with a Lasentec “Focused Beam Reflectance Measurement” (FBRM) probe developed by the same company. The FBRM probe “employs a rotating focused laser beam which is scattered back at individual particles at or close to the focal point of the laser beam.” Mathematical evaluation of the duration and intensity of the backscattered light is used to determine particle size distributions.

As the scientists explain, “While the FBRM technique delivers well-founded statistical data regarding the evolution of the particle size distribution over time, the PVM probe yields high-quality images providing detailed information on size and shape of the particle species being present in the respective stages of the polymerization process.” Methods for correlating the results with reaction kinetics were developed, and results from both probes compared well with those obtained from off-line monitoring for a variety of reaction scenerios. Although only polyethylene was investigated in this paper, application to other polyolefin slurry systems is expected to be straightforward. Application to copolymerization reactions is expected to yield exciting results.

Original publication: R. Xalter and R. Mülhaupt; "On-line Monitoring of Polyolefin Particle Growth in Catalytic Olefin Slurry Polymerization by means of LasentecTM Focused Beam Reflectance Measurement (FBRM) and Video Microscopy (PVM) Probes”; Macromol. React. Eng. 2010, 4, 25.

Most read news

Topics

Organizations

These products might interest you

CHSN-O, CN and N Elemental Analyzers by Velp Scientifica

State-of-the-art Elemental Analyzers for N, CN and CHSN-O in organic samples

Consistency, ease of use, and premium features for elemental analysis following official standards

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.