Printable sensors

In future every home will have one: electronic devices that you can control just by pointing a finger. To turn this vision into reality the 3Plast research consortium is developing special sensors that can be printed onto plastic film and affixed to objects.

The cellphone is switched off but immediately springs into action at the point of a finger. It is not necessary to touch the display. This touchless control is made possible by a polymer sensor affixed to the cellphone which, like human skin, reacts to the tiniest fluctuations in temperature and differences in pressure and recognizes the finger as it approaches.

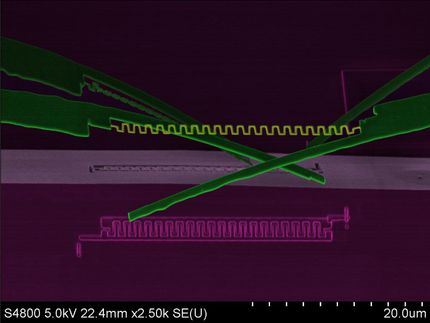

The scenario is fictitious at present but could become reality in a few years time thanks to the efforts of the research scientists involved in the EU project 3Plast, which stands for »Printable pyroelectrical and piezoelectrical large area sensor technology«. The companies and institutes involved from industry and research have set themselves the goal of mass producing pressure and temperature sensors which can be cheaply printed onto plastic film and flexibly affixed to a wide range of everyday objects, such as electronic equipment. The 2.2 million euro funded project is coordinated by the Fraunhofer Institute for Silicate Research ISC in Würzburg. »The sensor consists of pyroelectrical and piezoelectrical polymers which can now be processed in high volumes by screen printing, for example. The sensor is combined with an organic transistor, which strengthens the sensor signal. It’s strongest where the finger is,« explains Gerhard Domann, who is in charge of the project. »The special thing about our sensor is that the transistor can also be printed.«

The production of polymer sensors still poses a number of challenges. To produce printable transistors, the insulation materials have to be very thin. The experts at the ISC have, however, succeeded in producing an insulator which is only 100 nanometers thick. The first sensors have already been printed onto film. The research scientists are currently working on optimized transistors which can amplify rapid changes in temperature and pressure.

»By providing everyday objects with information about their environment – for example whether a person is approaching – by means of pressure and temperature sensors, we can create and market new devices that can be controlled just by pointing a finger,« enthuses Domann. The research scientist envisions further applications for the technology in the automotive and construction industries as well as in robotics. »The project comes to an end in January 2011, but we think it will take a few more years before sensors can be printed on large surfaces.«

Organizations

Other news from the department science

These products might interest you

CHSN-O, CN and N Elemental Analyzers by Velp Scientifica

State-of-the-art Elemental Analyzers for N, CN and CHSN-O in organic samples

Consistency, ease of use, and premium features for elemental analysis following official standards

HYPERION II by Bruker

FT-IR and IR laser imaging (QCL) microscope for research and development

Analyze macroscopic samples with microscopic resolution (5 µm) in seconds

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.