Scientists create 3D-printed, microscopic gas sensors - painters’ pallets without even a hint of pigment

"The tiny responsive arrays, which are smaller than a freckle, can be used to tell us an enormous amount about the chemistry of their environment”

Scientists from Trinity College Dublin and AMBER, the SFI Research Centre for Advanced Materials and BioEngineering Research, have discovered a way to fabricate tiny colour-changing gas sensors using new materials and a high-resolution form of 3D printing.

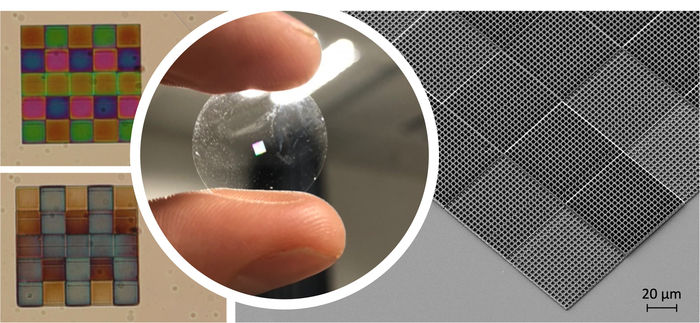

Centre: Photo of the glass substrate showing the colourful 3D printed sensor. Left: Zoomed-in optical microscopy images showing the pixelated sensor in response to different vapours; Right: Scanning electron microscopy image of the pixelated sensor, showing the different heights of the periodic structure.

Professor Florea, Trinity College Dublin and AMBER

The sensors – responsive, printed, microscopic optical structures – can be monitored in real-time, and used for the detection of solvent vapours in air. There is great potential for these sensors to be used in connected, low-cost devices for homes, or integrated in wearable devices used to monitor human health.

Most people spend much of their lives inside homes, cars, or work environments, so the ability to cheaply and accurately monitor levels of pollutants, for example, could be a game-changer within a health and wellbeing context.

The work was led by Larisa Florea, Assistant Professor in Trinity’s School of Chemistry, and Principal Investigator at AMBER, in collaboration with Louise Bradley, Professor in Trinity’s School of Physics, and carried out in CRANN, the Trinity Centre for Research on Adaptive Nanostructures and Nanodevices. An industrial collaborator and leader in the field of gas sensing, Dr Radislav Potyrailo from GE Research, Niskayuna New York, has also been involved throughout.

The team’s results have just been published as part of a Special Issue showcasing Professor Florea’s work as an Emerging Investigator in the Journal of Materials Chemistry C.

Lead author of the journal article, Dr Colm Delaney, from Trinity’s School of Chemistry and Research Fellow at AMBER, said: “More than 300 years ago, Robert Hooke first investigated the vibrant colours on a peacock’s wing. Only centuries later did scientists discover that the effervescent colouration was caused not by traditional pigments but by the interaction of light with tiny objects on the feather, objects which were just a few millionths of a metre in size.

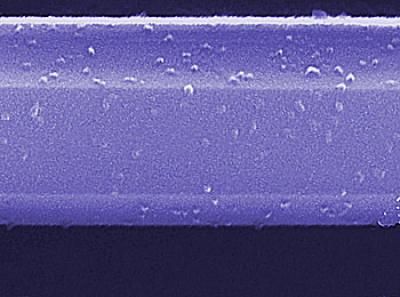

“We have taken this biological design, seen all the way from a magpie to a chameleon, to make some really exciting materials. We achieve this by using a technique known as Direct laser-writing (DLW), which allows us to focus a laser into an extremely small spot, and to then use it to make tiny structures in three dimensions from the soft polymers which we develop in the lab.”

Collaborator on the project, Professor of Photonics at Trinity, Louise Bradley, a funded investigator at AMBER, added: “The research we carry out between the two groups focuses on design, modelling, and fabrication of these tiny structures in stimuli-responsive materials. Jing Qian, a fantastic PhD student in my lab has spent a lot of time developing designs, and predicting the response of different structures, which we can have respond to light, heat, and humidity to create systems which can truly recreate the vividness, stealth response, and camouflaging ability found in nature. The tiny responsive arrays, which are smaller than a freckle, can be used to tell us an enormous amount about the chemistry of their environment.”

Why are tiny, coloured sensors useful?

While traditional physical sensors have bolstered a connected-living market, there exists a lag in low-cost, adaptable chemical-sensing platforms that can be used.

Photonic sensors have made considerable inroads into yielding accurate and robust alternatives, with minimal power consumption, low operating costs and high sensitivity. This is an area that Dr Potyrailo and GE Research have worked on commercialising for many years.

Professor Larisa Florea, from Trinity’s School of Chemistry and AMBER, said: “We have created responsive, printed, microscopic optical structures which can be monitored in real-time, and used for the detection of gases. The ability to print such an optically responsive material has profound potential for their incorporation into connected, low-cost sensing devices for homes, or into wearable devices for monitoring analytes.

“We spend the majority of our lives inside our homes, cars, or work environments. Models suggest that the concentration of pollutants can be anywhere from 5-100 times the concentration found outside. This is a haunting thought when we consider that the World Health Organisation suggests 90% of the world’s population lives in areas which exceed acceptable air standard limits. These pollutants can be influenced by ambient air, chemical presence, fragrances, food quality, and human activity and have a profound effect on our health.

“To date, indoor gas sensors have focused almost solely on leak, smoke, and carbon dioxide detection. Even iterative advances, to include relative humidity, oxygen levels, carbon dioxide, volatile organic carbons (VOCs), and ammonia in a real-time manner could play an enormous role in the development of a domestic environmental monitoring ecosystem. This could ensure that health and wellbeing monitoring become central to the future of home building and automation.”