Pure practice: Fritsch inspires with live demo for mechanical comminution and particle measurement!

Students from Geisenheim University visit FRITSCH

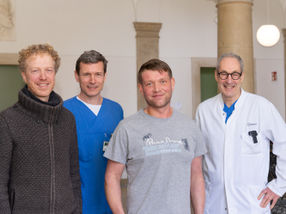

The University of Geisenheim is one of the leading universities in the field of viticulture, beverage technology, food production. 16 students including teachers of the master course food safety around Prof. Dr. Loos-Theisen followed the excursion invitation of FRITSCH GmbH - Milling and Sizing to visit a practical lecture day at the company headquarters in Idar-Oberstein.

FRITSCH

After the arrival and welcome by Mr. Dipl.- Ing. (FH) Holger Brecht, 2 theoretical, but nevertheless practical, lectures from the field of mechanical comminution as well as particle measurement took place. The industry-oriented relation of university & teaching to the daily business of an industrial partner is particularly close to the heart of Mrs. Doris Häge, M.Sc., as a research associate and organizer of the university institute. On this day, the focus was not on the classic lecture, but essentially on the interdisciplinary transfer of theoretical scientific knowledge in the context of daily customer inquiries from industry.

For example, the question was illuminated: "How PET bottles can be crushed with FRITSCH mills in the area of research and development in a resource-saving manner in order to produce new PET bottles again from the ground recyclate without any loss of quality".

The visitors found the presentation by Mr. Mike Paluga, M.Sc. (Phys.), on the subject of particle measurement and the associated quality assurance in the food industry particularly exciting.

The importance of the raw materials used in the production of chocolate was highlighted and how the particle size affects the mouthfeel, especially the melting.

After lunch, the participants went to the technical center of the specialist for application-oriented laboratory equipment. Here, various mills and their technology were presented. A special treat was the processing of vitamin candies with a liquid core into powder. With the aid of liquid nitrogen, the candies were processed into powder together with the liquid core in order to prepare them for subsequent vitamin analysis. These products are subject to special declaration requirements in regards to food safety and food laws, which is why the circle to the food safety course at the University of Geisenheim closed here.

Afterwards, all participants were able to enjoy a tour of the company's state-of-the-art machinery before the return journey to the Rheingau region.

"It was a successful and exciting event. We hope for a continued lively exchange of information in the future, gladly also with joint projects or other industrial partners from the Nahe, Hunsrück and Hochwald region," said Prof. Dr. Loos-Theisen after handing the certificates of participation were presented. "Thank you again for accepting our invitation. We are always pleased to pass on our knowledge and cooperate with universities and colleges," said Dipl.- Ing. (FH) Holger Brecht.

We are more than glad to hold such practical lecture days or similar events for students in our application technology laboratory.

Most read news

Other news from the department business & finance

These products might interest you

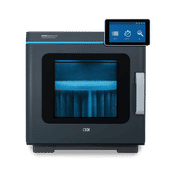

MARSXpress 2.0 by CEM

Intelligent Microwave Digestion System for Maximum Flexibility and Efficiency

From Single Sample to High Throughput - Optimal Results at the Push of a Button

HYDROTHERM by C. Gerhardt

Efficiency in food analysis: Safe and precise total fat determination made easy

Fully automatic acid hydrolysis in 90 minutes - validated for continuous operation

VICI DBS ZeroAir by VICI

Generate up to 30 L/min of analytically pure air yourself – for stable baseline GC-FID applications

Increase the sensitivity of your GC-FID analysis while reducing costs

APU sim by Analytik Jena

APU sim Automatic Preparation Unit

APU sim The Clever Sample Preparation System According to Column Method

OHAUS Laboratory equipment by Ohaus

Do More with OHAUS Laboratory Equipment

Do Not Limit Yourself to Just Measurement! Discover Ingenious Portfolio

FlowSyn and FlowSyn Maxi by Uniqsis

Continuous Flow Chemistry Systems for reaction optimisation and scale up

Perform reactions up to 300°C and 100 bar from 0.1 - 100 ml /minute

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.