Optical measurement of forces in plastics

Fascinating "molecular springs": research team develops dyes that quantitatively indicate stresses in plastics

Under the leadership of Prof. Dr. Michael Sommer, Chair of polymer chemistry at Chemnitz University of Technology, a research team has succeeded in constructing various dye molecules from the field of so-called mechanophores and using them to quantitatively display molecular stresses. With the help of such molecules, component stresses become visible through color changes depending on their strength.

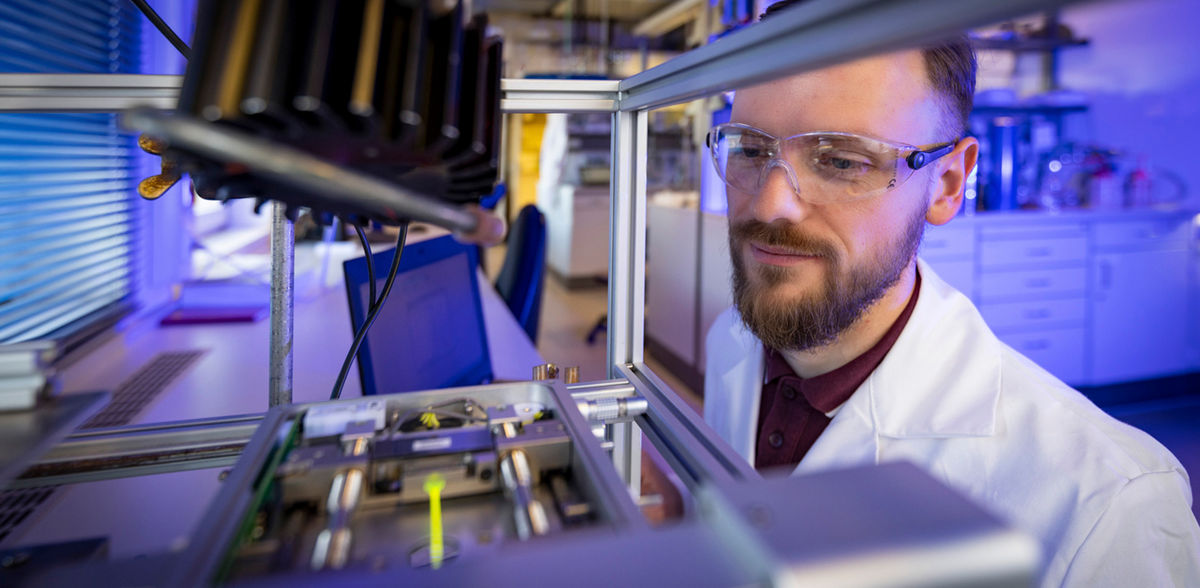

The color of the sample changes depending on the force. Responsible for this are dye molecules from the area of so-called mechanophores, which make changing component stresses visible through color changes.

Jacob Müller

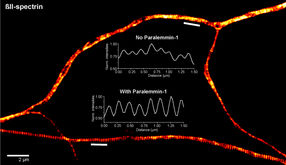

The concept of such dyes is not new. However, previous mechanophores were usually only able to indicate the presence or absence of stresses in plastics. For some years now, however, the Department of Polymer Chemistry has been developing molecular torsion springs, which are proving to be a particularly suitable and promising class of mechanophores. The dye molecules "feel" the force acting within a plastic and indicate mechanical stress by changing color. If the force on the plastic decreases, the dye molecules return to their original state. This is why these dyes are also known as "molecular springs" - they stretch and then "spring" back to their original state.

In earlier work at the Chair of Polymer Chemistry, mechanical stresses in plastics could already be made continuously visible and molecular forces could be derived from the theory. "This brings great advantages wherever it is important to map stresses in plastics in real time. This new form of damage analysis could soon lead to practical applications," says Sommer.

Calibration of molecular torsion springs enables quantitative force measurement

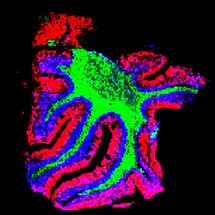

In the current research work, which was published in the journal Angewandte Chemie, this concept is being further developed through the experimental calibration of forces. This allows the magnitude of forces in different plastics to be determined optically. "The step from mere visualization and theoretically calculated forces in plastics to experimentally directly determined forces is a big one," assures Sommer. This was made possible by the use of differently functioning mechanophores, whose behavior under certain mechanical stresses can be compared with each other. In this way, molecular forces could be determined. So far, tensile forces have been the main focus of investigation. The extent to which external compressive forces, for example, can also be determined reliably and quantitatively still needs to be researched.

Better mechanical properties, ageing of plastics and damage analysis

The results form a broad basis for an even better fundamental understanding of forces in polymer materials. In further experiments carried out as part of a recently funded DFG project together with the working groups of Prof. Günter Reiter (Polymer Physics) and Priv.-Doz. Michael Walter (Theory) at the University of Freiburg, microscopic force distributions in various plastics will be investigated and 3D-printed components will also be used. "The visualization of time- and spatially-resolved force distributions can only be modelled theoretically so far. The use of torsion springs offers unique opportunities for microscopic insights that could revolutionize aging and damage analysis," says Sommer.

He is particularly pleased about the very high scientific contribution of first author Raphael Hertel, who designed and experimentally carried out large parts of the work as a doctoral student in the Department of Polymer Chemistry. "It's always a great pleasure to see someone from the working group working on such successful projects independently," says Sommer.

Note: This article has been translated using a computer system without human intervention. LUMITOS offers these automatic translations to present a wider range of current news. Since this article has been translated with automatic translation, it is possible that it contains errors in vocabulary, syntax or grammar. The original article in German can be found here.