New X-ray technique may lead to better, cleaner fuel injectors for automobiles

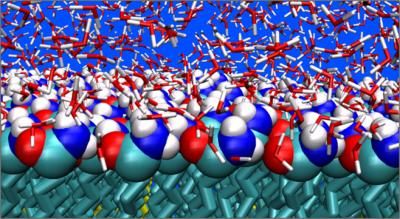

Standard microscopy and visible light imaging techniques cannot peer into the dark and murky centers of dense-liquid jets, which has hindered scientists in their quest for a full understanding of liquid breakup in devices such as automobile fuel injectors. Scientists at the U.S. Department of Energy's (DOE) Argonne National Laboratory have developed a technique to peer through high-speed dense liquids using high-energy X-rays from Argonne's Advanced Photon Source (APS).

"The imaging contrast is crisp and we can do it orders of magnitude faster than ever before," Argonne X-ray Science Division physicist Kamel Fezzaa said.

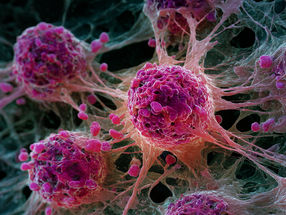

Fuel injector efficiency and clean combustion is dependent on the best mixture of the fuel and air. To improve injector design, it is critical to understand how fuel is atomized as it is injected. However, standard laser characterization techniques have been unsuccessful due to the high density of the fuel jet near the injector opening. Scientists have been forced to study the fuel far away from the nozzle and extrapolate its dispersal pattern. The resulting models of breakup are highly speculative, oversimplified and often not validated by experiments.

Fezzaa and his colleagues, along with collaborators from Visteon Corp. developed a new ultrafast synchrotron X-ray full-field phase contrast imaging technique and used it to reveal instantaneous velocity and internal structure of these optically dense sprays. This work is highlighted in Nature Physics.

A key to the experiment was taking advantage of the special properties of the X-ray beam generated at the APS. Unlike hospital x-rays, the synchrotron x-rays are a trillion times brighter and come in very short pulses with durations as little as 0.1 nanoseconds.

"The main challenge that our team had to overcome was to be able to isolate single x-ray pulses and use them to do experiments, and at the same time protect the experimental setup from being destroyed by the overwhelming power of the full x-ray beam," Fezzaa said.

Their new technique has the ability to examine the internal structure of materials at high speed, and is sensitive to boundaries. Multiphase flows, such as high-speed jets or bubbles in a stream of water, are ideal systems to study with this technique. Other applications include the dynamics of material failure under explosive or ballistic impact, which is of major importance to transportation safety and national security, and material diffusion under intense heat.

Most read news

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.