Huntsman wins top prize at IChemE awards

Huntsman Pigments Division clinched the top prize at the Institution of Chemical Engineers (IChemE) 2008 Innovation and Excellence Awards in Birmingham, UK. The Huntsman team won the Entec medal for creating Deltio – a free-flowing chemical form of titanium dioxide (TiO2).

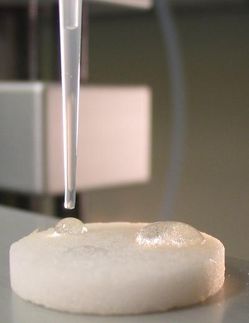

Deltio is an effective form of titanium dioxide, without the handling and poor flow properties commonly associated with TiO2. The new product has already been scaled-up to industrial levels.

Steven Stanley and Abdul Latif won IChemE’s top individual prizes. Stanley celebrated a double triumph thanks to his radball – an instrument that can map radiation hazards in laboratories. Latif, based at the Universiti Sains Malaysia, won the NES Novel Engineering Solutions Award for his research into minimising pollution from industrial wastewater.

Latif has invented a zero-discharge system for palm oil mill effluent, making Malaysia’s considerable palm oil industry more sustainable. The membrane returns around 85% of the effluent as clean water, suitable for drinking or recycling within the mill.

Latif has also developed Flocsorb, an environmentally-friendly product, to replace alum and polyaluminium chloride in water treatment plants. Flocsorb allows a plant’s sludge to be used to fertilise fields rather than be disposed of as waste. A Swedish company now wants to trial Latif’s designs in a pilot plant at one of Malaysia’s palm oil mills.

Stanley, who works for the UK’s National Nuclear Laboratory, was part of a team effort that clinched the HFL Risk Services Health & Safety Award, before also lifting the GSK Young Engineer of the year award.

Stanley’s radball marks an innovative step forward in the detection of radiation in nuclear facilities. Traditional methods involve sending an operator into the contaminated area with a hand-held device or using a heavy, expensive imaging device.

The cost-effective radball is the size of an orange and consists of an inner spherical core and an outer collimation sheath. It needs no electricity and can be used in intensely contaminated and hard-to-reach zones. Radiation passing through the sheath creates opacity tracks, analysed by a computer to determine radiation location, type and intensity.

31-year-old Stanley has been a research Fellow at the laboratory for five years and his development of the radball has attracted new business and interest to the Nuclear Laboratory.

Other winners included Shell Global Solutions (Sellafield Ltd Engineering Excellence award); the University of Nottingham – (Petronas Education Excellence Award); Haemair Ltd (Stopford Projects Bioprocess Innovation Award); BP Alternative Energy (SRG Food & Drink Engineering Innovation Award); Arvia Technology Ltd (IChemE Water Award); Jacobs Engineering UK (Shell Energy Award); the National Nuclear Laboratory (HFL Risk Health & Safety Excellence Award); and Faculdade de Engenharia da Universidade do Porto (ABB Consulting Sustainable Technology Award).

Topics

Organizations

Other news from the department business & finance

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.