Tracing ultra-fine dust

Limit values for fine dust emissions are based on total particle weight. It is the ultra-fine particles, however, that are particularly harmful to health. A new technique separates them by size and identifies their composition - directly where they arise.

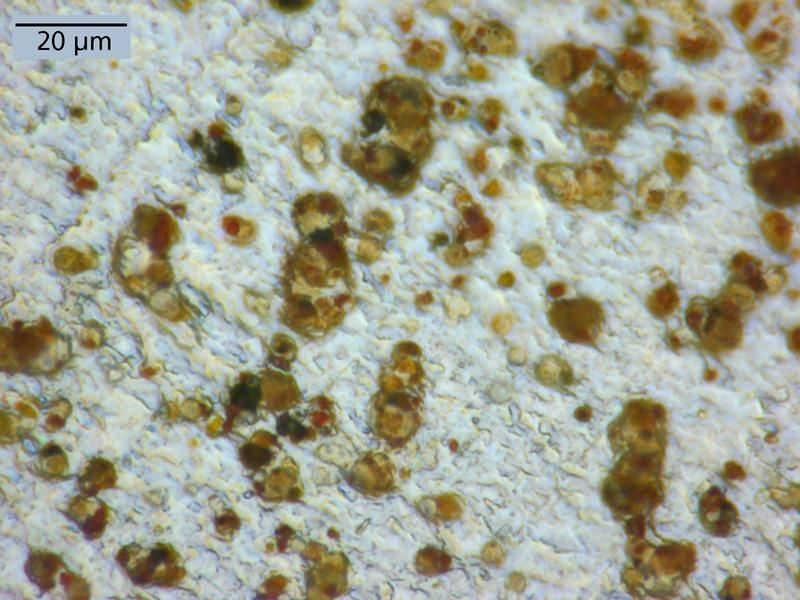

Microscope image of dust particles collected on a filter.

© Fraunhofer ILT

Fine particle emissions have been the subject of heated debate for years. People who live near industrial plants see the smoke being discharged into the atmosphere and wonder how harmful it is. But visible emissions are not always the most harmful. The highest risk is posed by fine dust particles which can easily penetrate the human organism. These ultra-fine particles are difficult to measure, however, because they are less than 100 nanometers in diameter.

Research scientists at the Fraunhofer Institute for Laser Technology ILT in Aachen have developed a technique by which the composition of such particles can be precisely analyzed. “The statutory limit values for fine particle emissions are based on the total particle weight,” explains Dr. Cord Fricke-Begemann, project manager at the ILT. “Large particles are, however, much heavier than small ones. Weight measurements do not provide any information on the quantity of ultra-fine particles in the fine dust, but they are often more harmful than the larger particles.”

The measurement technique developed by the research scientists consists of two steps. A gas stream separates the particles into size classes before they are collected on filters. Their composition is then examined by means of laser emission spectroscopy. “We are therefore able to identify harmful heavy and transition metals, such as zinc, in the fine dust, and also to ascertain the particle size at which they become particularly enriched,” explains Fricke-Begemann. A key aspect of the method is that it delivers the results in less than 20 minutes. What’s more, it can work at a high throughput rate and enables measurements to be taken directly on site - e.g. in steel plants. Emission values can be measured and monitored in real time during production thanks to a further development of the technique in which the particles are continuously drawn off via an air tube and analyzed.

All industrial plants produce fine dust emissions, and every process leaves behind a characteristic “fingerprint” of the particle composition and size distribution. With their measurement method the scientists can test the air in nearby residential areas and identify where the particles are from. They can also help to develop strategies for reducing emissions from the plants concerned.

Most read news

Other news from the department science

These products might interest you

FIBRETHERM by C. Gerhardt

Automatic Fibre Extraction for Feed Analysis

FIBRETHERM from C. Gerhardt: Efficient – Precise – Method-Compliant

Microbiology QC products by Cytiva

Efficient membrane filtration for food and beverage testing

Optimize your laboratory tests with versatile filtration systems

VICI Jour Katalog 15INT by VICI

The VICI Jour Catalog - Accessories for (U)HPLC and Liquid Handling

Capillaries, Tubing, Fittings, Filters, Safety-Products, Tools and much more

Hahnemühle LifeScience Catalogue Industry & Laboratory by Hahnemühle

Wide variety of Filter Papers for all Laboratory and Industrial Applications

Filtration Solutions in the Life Sciences, Chemical and Pharmaceutical Sectors

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.