Materials research advances reliability of faster 'smart sensors'

In military and security situations, a split second can make the difference between life and death, so North Carolina State University's development of new "smart sensors" that allow for faster response times from military applications is important. Equally important is new research from NC State that will help ensure those sensors will operate under extreme conditions – like those faced in Afghanistan or elsewhere.

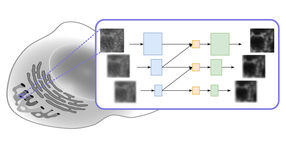

"We've taken a sensor material called vanadium oxide and integrated it with a silicon chip," says Dr. Jay Narayan, the John C. Fan Distinguished Chair Professor of Materials Science and Engineering at NC State and co-author of the research. "Normally sensors are hardwired to a computer. But now the sensor is part of the computer chip itself. The advantage is that now you have a smart sensor that can sense, manipulate and respond to information."

For example, such smart sensors allow for the development of infrared sensors that can respond more quickly in military or security applications.

The creation of these smart sensors is possible due to Narayan's discovery of "domain matching epitaxy." This model allows the creation of single, defect-free crystal layers of different materials – which amplify the transmission of electronic signals between those materials.

New findings presented by a team of NC State researchers (published in Applied Physics Letters and Journal of Applied Physics) now describe how vanadium oxide sensors work in conjunction with the silicon chips to which they are attached. Understanding how these sensors function gives researchers the ability to improve the reliability of these smart sensors, and account for variable conditions the sensors may be exposed to, such as various temperatures and pressures a sensor may face in Afghanistan or Iraq.

Most read news

Other news from the department science

Get the analytics and lab tech industry in your inbox

From now on, don't miss a thing: Our newsletter for analytics and lab technology brings you up to date every Tuesday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.

![[Fe]-hydrogenase catalysis visualized using para-hydrogen-enhanced nuclear magnetic resonance spectroscopy](https://img.chemie.de/Portal/News/675fd46b9b54f_sBuG8s4sS.png?tr=w-712,h-534,cm-extract,x-0,y-16:n-xl)