Seeing moire in graphene

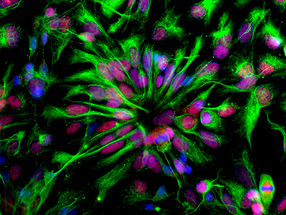

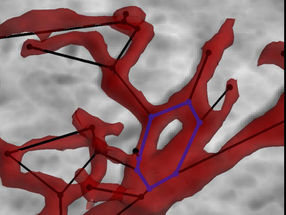

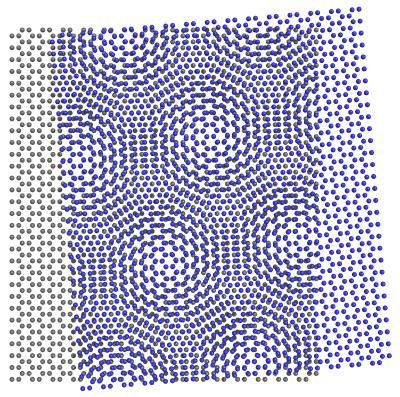

Researchers at the National Institute of Standards and Technology (NIST) and the Georgia Institute of Technology have demonstrated that atomic scale moiré patterns, an interference pattern that appears when two or more grids are overlaid slightly askew, can be used to measure how sheets of graphene are stacked and reveal areas of strain. The ability to determine the rotational orientation of graphene sheets and map strain is useful for understanding the electronic and transport properties of multiple layers of graphene, a one-atom thick form of carbon with potentially revolutionary semiconducting properties.

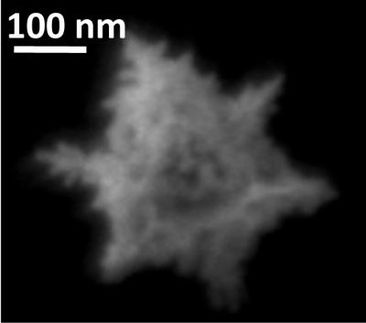

Moiré patterns appear when two or more periodic grids are overlaid slightly askew, which creates a new larger periodic pattern. Researchers from NIST and Georgia Tech imaged and interpreted the moiré patterns created by overlaid sheets of graphene to determine how the lattices of the individual sheets were stacked in relation to one another and to find subtle strains in the regions of bulges or wrinkles in the sheets.

NIST

In digital photography, moiré (pronounced mwar-ray) patterns occur because of errors in the rendering process, which causes grid patterns to look wavy or distorted. Materials scientists have been using microscopic moiré patterns to detect stresses such as wrinkles or bulges in a variety of materials.

Researchers created graphene on the surface of a silicon carbide substrate at the Georgia Institute of Technology by heating one side so that only carbon, in the form of multilayer sheets of graphene, was left. Using a custom-built scanning tunneling microscope at NIST, the researchers were able to peer through the topmost layers of graphene to the layers beneath. This process, which the group dubbed "atomic moiré interferometry," enabled them to image the patterns created by the stacked graphene layers, which in turn allowed the group to model how the hexagonal lattices of the individual graphene layers were stacked in relation to one another.

Unlike other materials that tend to stretch out when they cool, graphene bunches up like a wrinkled bed sheet. The researchers were able to map these stress fields by comparing the relative distortion of the hexagons of carbon atoms that comprise the individual graphene layers. Their technique is so sensitive that it is able to detect strains in the graphene layers causing as little as a 0.1 percent change in atom spacing.

Original publication: D. Miller, K. Kubista, G. Rutter, M. Ruan, W. de Heer, P. First and J. Stroscio; "Structural analysis of multilayer graphene via atomic moiré interferometry"; Physical Review B. 81. 125427. Published March 24, 2010

Most read news

Topics

Organizations

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.

![[Fe]-hydrogenase catalysis visualized using para-hydrogen-enhanced nuclear magnetic resonance spectroscopy](https://img.chemie.de/Portal/News/675fd46b9b54f_sBuG8s4sS.png?tr=w-712,h-534,cm-extract,x-0,y-16:n-xl)