When soft spheres make porous media stiffer

Researchers of the University of Stuttgart and the University if Twente succeed in three-dimensional characterization

Porous media such as concrete physically represent a spherical packing of different components – in this case cement, rock and water. The mechanical properties of such mixtures are still difficult to calculate due to their discretized nature. A team led by Prof. Holger Steeb (University of Stuttgart) and Prof. Stefan Luding (University of Twente, The Netherlands) has now been able to investigate an unexpected property of mixtures of granular media consisting of soft and stiff spherical particles. For this purpose, a combination of ultrasound investigations and X-ray computed tomographic imaging was employed, allowing a three-dimensional (3D) characterization and evaluation. The journal PNAS reported on this. The discovery could contribute to safer future building in earthquake zones.

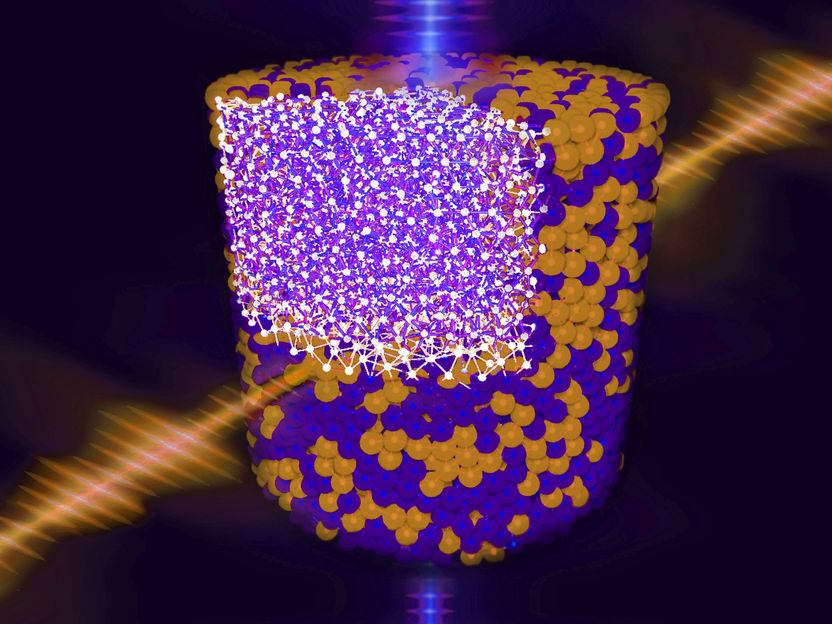

Sphere packing with soft and stiff spheres whose effective mechanical properties are studied by means of ultrasonic waves and X-rays.

Universität Stuttgart/Matthias Ruf, University of Twente, Dr. Kianoosh Taghizadeh

The analysis of the exact composition of porous materials, such as concrete or asphalt, and its influence on resulting mechanical material properties plays an extremely crucial role in various technical applications. Because only by knowledge about the exact mixture ratio and the resulting effective material behavior such porous materials can be adapted to specific “application requirements”. For example, when a composite material consists of a soft polymer matrix with stiff reinforcing fibers, the effective elastic stiffness of the composite material can be increased by increasing the fiber content. The resulting effective stiffness can be experimentally determined non-destructively from the wave travel time of a sound pulse through the granular spherical packing.

Enhanced predictive models through targeted experimental investigations

In this context, the teams of Prof. Holger Steeb, principal investigator in the Collaborative Research Center 1313 as well as in the Center of Excellence SimTech (EXC 2075), and Prof. Stefan Luding (University of Twente, The Netherlands) investigate the effective elastic properties of spherical packings using ultrasound in the "Porous Media Lab" at the University of Stuttgart. Dr. Kianoosh Taghizadeh and Matthias Ruf from the Chair of Continuum Mechanics are part of the Stuttgart team.

In the experiment, the researchers first prepared spherical packings of equally sized stiff glass spheres and soft rubber spheres in different mixing ratios. These packings were mechanically investigated into an X-ray transparent (PMMA) cylinder equipped with piezoelectric ultrasonic sensors and actuators under defined axial loading conditions. Interestingly, it turned out that adding up to 20 per cent (soft) rubber spheres has not reduced the effective stiffness of the packings, but improved it. However, when the fraction of the rubber spheres is more than 30 percent, the stiffness begins to decrease since the overall network is no longer dominated by stiff particles. „This behavior contradicts all classical mixing rules”, underlines Holger Steeb. "To gain a better understanding of the unexpected mechanical response, the overall network of particles (force network), including the glass and rubber sub-networks have been analyzed.”

No longer a classic solid material

The researchers successfully evaluated the morphology by combining ultrasound examinations with X-ray Computed Tomographic imaging characterization (XRCT). X-ray images have shown that the higher effective stiffness of the packings with rubber fractions of up to 20 percent can be explained by the length of force chains of glass particles. „At the same time, the glass particles network is in a so-called "jammed state" with a correspondingly high coordination number. If the volume fraction of the rubber spheres rises above 30 per cent, the force chains consist of mixed contacts between glass and rubber spheres, which are much softer. “

Furthermore, the evaluation of the local sphere neighborhoods showed that the coordination number, i.e. the number of neighboring spheres of the same type, becomes significantly smaller at these higher volume fractions. "At this volume fraction, neither of the two spherical phases is in a jammed state and thus the effective material behavior is not comparable to a classical solid", conclude Holger Steeb. The scientists see a lot of practical potential for the building industry in the further development of this research. For example, in earthquake-prone areas, the stiffness and damping properties of soils could be adjusted through specific composite ballast-rubber mixtures. The amplitudes and velocities of earthquake waves could be manipulated in a targeted manner. Buildings could be protected from these dangers efficiently and cost-effectively.