Microfluidic breakthrough in biotechnology

Chemical flasks and inconvenient chemostats for cultivation of bacteria are likely soon to be discarded. Researchers from the Institute of Physical Chemistry of the Polish Academy of Sciences in Warsaw were first to construct a microfluidic system allowing for merging, transporting and splitting of microdroplets. Since now, hundreds of different bacteria cultures can be maintained simultaneously in a single system, which could speed up the research on restistance of bacteria to antibiotics.

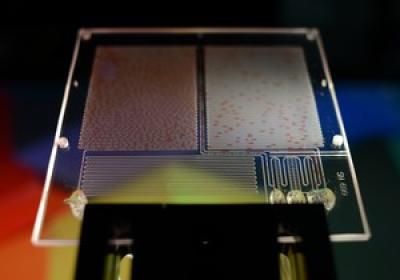

The first microfluidic system capable of merging, mixing and splitting microdroplets has been fabricated in the Institute of Physical Chemistry of the Polish Academy of Sciences in Warsaw. The system allows for cultivation of different bacteria in different microdroplets. The part of the device used for merging and splitting the microdroplets is in the right lower corner of the plate.

IPC PAS, Grzegorz Krzyżewski

We could safely say that without chemical flask there would be no chemistry at all. It has been since years, however, the chemists' dream to be able to downscale to the microscale the operations that are easily performed with large quantities of chemicals inside flasks, including refilling, mixing, pouring out. The first microfluidic system capable of performing all the typical operations with chemicals inside miniscule droplets has been presented just now. The device, fabricated by a group of researchers from the Institute of Physical Chemistry of the Polish Academy of Sciences (IPC PAS), headed by Dr Piotr Garstecki, allow for performing strictly controlled chemical reactions and cultivation of bacterial colonies inside multiple microdroplets at a time.

The research paper reporting a system for cultivation of bacteria have just been published in one of the most prestigious chemical journals, "Angewandte Chemie International Edition".

Microfluidic systems are fabricated from polymer plates with sizes resembling a credit card or less. Inside the systems, a carrier fluid (mostly oil) carrying microdroplets containing chemicals flows laminarly through tiny channels of diameters in the range of tenths or hundredths of a milimeter. Using a single microfluidic system, up to a few dozen of thousands of different chemical reactions can be carried out during a day.

Existing microfluidic systems featured a serious drawback: they did not allow to carry out and control long-lasting processes requiring to perform thousands of operations on each of hundreds of microdroplets. Due to this limitation, e.g., long-lasting cultivations of microorganisms were not possible. To provide bacteria with normal growth conditions, they must be supplied with nutrients, and metabolites must be removed from their environment on a regular basis.

"Our microfluidic system allows to add to and to collect from each of hundreds of droplets circulating within the device a precisely measured amount of fluid", says Dr Garstecki.

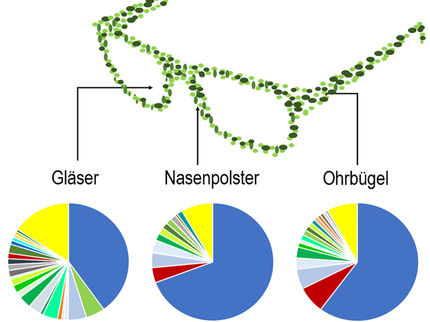

The microsystem from the IPC PAS is composed of two branches of microchannels forming densely arranged zigzags. Up to a few hundred droplets, at a distance of about one centimeter from each other, can circulate in the microchannels. The microdroplets move in a pendular movement from one branch to the other.

Most read news

Organizations

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.