World's smallest universal material testing system

The design, development and manufacturing of revolutionary products such as the automobile, airplane and computer owe a great deal of their success to the large-scale material testing systems (MTS) that have provided engineers and designers with a fundamental understanding of the mechanical behavior of various materials and structures.

In the world of nanotechnology, however, where the mechanical characterization of materials and structures takes place on the scale of atoms and molecules, the existing material testing systems are useless. The development of a universal nanoscale material testing system (n-MTS), which could fit in existing electron microscopes and possess the resolution and accuracy needed to mechanically test nanoscale objects, has been a major challenge within the scientific community.

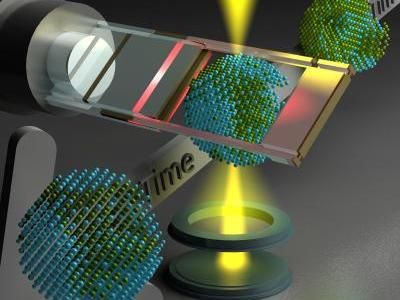

Now researchers at Northwestern University have designed and built the first complete micromachine that makes possible the investigation of nanomechanics phenomena in real time. The findings are published online by the Proceedings of the National Academy of Sciences (PNAS). The machine, which can fit in tiny spaces as required by in situ transmission electron microscopy (TEM), successfully characterized the mechanical properties of nanowires and carbon nanotubes.

The n-MTS developed by Horacio D. Espinosa, professor of mechanical engineering, and his colleagues consists of an actuator and a load sensor fabricated by means of micro technology. The load sensor is based on differential capacitive sensing, which provides a load resolution of about 10 nano Newtons. This is the first nanoscale material testing system that provides continuous observation of specimen deformation and failure with sub-nanometer resolution while simultaneously measuring electronically the applied forces with nano-Newton resolution. The integration of electro-mechanical and thermo-mechanical components at the micro scale made the achievement possible.

One of the challenges overcome by the University researchers was the integration of micro-electro-mechanical systems (MEMS) and circuits for measurement of electronic signals. They solved this problem by using a double-chip architecture consisting of a MEMS chip and a microelectronic sensing chip. Another challenge overcome by the team was the mounting of individual nanostructures on the testing device. Using a nanomanipulator inside a dual-beam scanning electron microscope and focused ion beam apparatus the researchers picked up nanostructures, cut them to the desired length and nanowelded the structures onto the n-MTS using electron-beam-induced deposition of platinum.

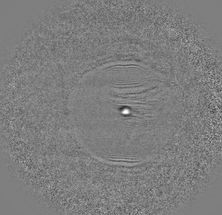

As reported in the PNAS paper, the system capabilities were demonstrated by in situ electron microscopy testing of free-standing polysilicon films, metallic nanowires and carbon nanotubes (CNTs). Espinosa's team achieved the first real-time instrumented in situ transmission electron microscopy observation of CNTs failure under tensile loading.

Most read news

Topics

Organizations

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.