Leeds researchers fuelling the 'hydrogen economy'

Scientists at the University of Leeds are turning low-grade sludge into high-value gas in a process which could make eco-friendly biodiesel even greener and more economical to produce. Biodiesel - motor fuel derived from vegetable oil - is a renewable alternative to rapidly depleting fossil fuels. It is biodegradable and non-toxic, and production is on the up. But for each molecule of biodiesel produced, another of low-value crude glycerol is generated, and its disposal presents a growing economic and environmental problem.

Now researchers Leeds have shown how glycerol can be converted to produce a hydrogen rich gas. Hydrogen is in great demand for use in fertilisers, chemical plants and food production. Moreover, hydrogen is itself viewed as a future 'clean' replacement for hydrocarbon-based transport fuels, and most countries currently reliant on these fuels are investing heavily in hydrogen development programmes.

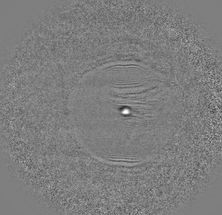

The novel process developed by Dr Valerie Dupont and her co-investigators in the University's Faculty of Engineering mixes glycerol with steam at a controlled temperature and pressure, separating the waste product into hydrogen, water and carbon dioxide, with no residues. A special absorbent material filters out the carbon dioxide, which leaves a much purer product.

"Hydrogen has been identified as a key future fuel for low carbon energy systems such as power generation in fuel cells and as a transport fuel. Current production methods are expensive and unsustainable, using either increasingly scarce fossil fuel sources such as natural gas, or other less efficient methods such as water electrolysis."

"Our process is a clean, renewable alternative to conventional methods. It produces something with high value from a low grade by-product for which there are few economical upgrading mechanisms" says Dr Dupont. "In addition, it's a near 'carbon-neutral' process, since the CO2 generated is not derived from the use of fossil fuels."

Dr Dupont believes the process is easily scalable to industrial production, and, as the race towards the 'hydrogen economy' accelerates, could potentially be an economically important, sustainable - and environmentally friendly - way of meeting the growing demand for hydrogen.

Dr Dupont's research has been funded with a £270k grant from the Engineering and Physical Sciences Research Council (EPSRC) under the Energy programme, and is in collaboration with Professors Yulong Ding and Mojtaba Ghadiri from the Institute of Particle Science and Engineering, and Professor Paul Williams from the Energy and Resources Research Institute at the University. Industrial collaborators are Johnson Matthey and D1-Oils.

Most read news

Topics

Organizations

Other news from the department science

These products might interest you

Mini-UniPrep™ by Cytiva

Improved HPLC sample preparation

Save 66% sample preparation time and reduce costs by 40%

FIBRETHERM by C. Gerhardt

Automatic Fibre Extraction for Feed Analysis

FIBRETHERM from C. Gerhardt: Efficient – Precise – Method-Compliant

VICI Jour Katalog 15INT by VICI

The VICI Jour Catalog - Accessories for (U)HPLC and Liquid Handling

Capillaries, Tubing, Fittings, Filters, Safety-Products, Tools and much more

Hahnemühle LifeScience Catalogue Industry & Laboratory by Hahnemühle

Wide variety of Filter Papers for all Laboratory and Industrial Applications

Filtration Solutions in the Life Sciences, Chemical and Pharmaceutical Sectors

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.