Nanotechnologists from Penn collaborate to form near-frictionless diamond material

Researchers at the University of Pennsylvania, the University of Wisconsin-Madison and IBM Research-Zürich have fabricated an ultra sharp, diamond-like carbon tip possessing such high strength that it is 3,000 times more wear-resistant at the nanoscale than silicon.

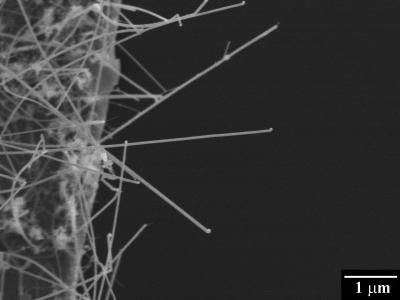

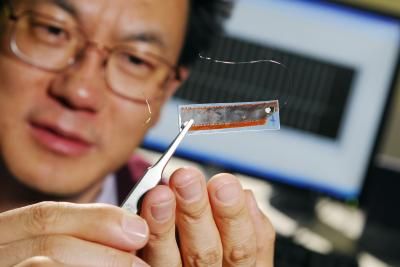

The end result is a diamond-like carbon material mass-produced at the nanoscale that doesn't wear. The new nano-sized tip, researchers say, wears away at the rate of one atom per micrometer of sliding on a substrate of silicon dioxide, much lower than that for a silicon oxide tip which represents the current state-of-the-art. Consisting of carbon, hydrogen, silicon and oxygen molded into the shape of a nano-sized tip and integrated on the end of a silicon microcantilever for use in atomic force microscopy, the material has technological implications for atomic imaging, probe-based data storage and as emerging applications such as nanolithography, nanometrology and nanomanufacturing.

The importance of the discovery lies not just in its size and resistance to wear but also in the hard substrate against which it was shown to perform well when in sliding contact: silicon dioxide. Because silicon –- used in almost all integrated circuit devices –- oxidizes in atmosphere forming a thin layer of its oxide, this system is the most relevant for nanolithography, nanometrology and nanomanufacturing applications.

Probe-based technologies are expected to play a dominant role in many such technologies; however, poor wear performance of many materials when slid against silicon oxide, including silicon oxide itself, has severely limited usefulness to the laboratory.

Researchers built the material from the ground up, rather than coating a nanoscale tip with wear-resistant materials. The collaboration used a molding technique to fabricate monolithic tips on standard silicon microcantilevers. A bulk processing technique that has the potential to scale up for commercial manufacturing is available.

Robert Carpick, professor in the Department of Mechanical Engineering and Applied Mechanics at Penn, and his research group had previously shown that carbon-based thin films, including diamond-like carbon, had low friction and wear at the nanoscale; however, it has been difficult to fabricate nanoscale structures made out of diamond-like carbon until now.

Understanding friction and wear at the nanoscale is important for many applications that involve nanoscale components sliding on a surface.

"It is not clear that materials that are wear-resistant at the macroscale exhibit the same property at the nanoscale," lead author Harish Bhaskaran, who was a postdoctoral research at IBM during the study, said.

Defects, cracks and other phenomena that influence material strength and wear at macroscopic scales are less important at the nanoscale, which is why nanowires can, for example, show higher strengths than bulk samples.

Most read news

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.