Optimized analytics reduce “false negatives” in the detection of nanoparticles

The INM – Leibniz Institute for New Materials has joined forces with a manufacturer of analytical equipment to reduce particles losses and avoid false negatives. They developed reference nanoparticles and used them to investigate how the analysis can be improved.

Many everyday products and our environment contain nanoparticles, and there is increasing interest in finding them. The particles and their sizes are commonly detected using specialized analytical techniques. If nanoparticles are lost in the analytical apparatus, they are not detected, and a “false negative” result occurs. The INM – Leibniz Institute for New Materials has joined forces with a manufacturer of analytical equipment to reduce particles losses and avoid false negatives. They developed reference nanoparticles and used them to investigate how the analysis can be improved.

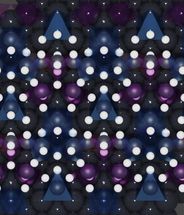

In project DINAFF, researchers at INM and Superon GmbH managed to reduce the loss of nanoparticles during analysis and, therefore, to improve the limit of detection. The researchers modified the inner surface of the analytical apparatus, optimized measurement parameters such as flow speed, and tuned the surface properties of the target nanoparticles.

“We worked with so-called tracer particles for our analyses,” Tobias Kraus from INM explained. “These are nanoparticles that we deliberately add to each sample. We therefore know that we should be able to find these particles in the sample. If we do not find them, something during the analysis impedes detection and causes a false negative.” Parameters of the analytical method then have to be adjusted so that the tracer particles become detectable. The head of the Structure Formation group continued: “The more similar our tracer particles are to the real nanoparticles, the more reliably the real nanoparticles can be detected later.”

The researchers applied the so-called AF4 Method to detect nanoparticles. In this method, nanoparticles are lost when they adhere to tubing or other internal surfaces of the apparatus and no longer arrive at the detector. Nanoparticles may also form clumps that are so large that the detector no longer responds to them. “Preventing these two main causes of false negatives requires a combination of suitable tracer particles, the right analytical method, and optimized parameters,” Kraus says.

In the future, the researchers will offer their expertise in all three areas to interested parties from industry. They will provide the synthesis of tracer particles, consultation regarding analysis of the industrial partners, and particle analysis as a service at INM.

Organizations

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.