Under pressure, atoms make unlikely alloys

Ever since the Bronze Age, humans have experimented with combining different metals to create alloys with properties superior to either metal alone. But not all metals readily form alloys - for some pairs of elements the atoms are too dissimilar. Now researchers in an international team have discovered that previously impossible alloys can be created by subjecting atoms to high pressure - opening up possibilities for new materials in the future.

Previous studies have shown that at pressures thousand of times larger than atmospheric pressure atoms change their properties and combine under different rules, creating new materials. But the cerium-aluminum alloy produced at the Carnegie Institution's Geophysical Laboratory breaks new ground in the development of alloys.

"The boundary has been pushed before - but not to this extreme," says Carnegie's Ho-kwang Mao, who with Jian-zhong Jiang of the International Center for New-Structured Materials, Zhejiang University, China, led the research team which also included scientists from Stanford University and Uppsala University, Sweden.

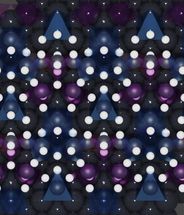

Most alloys are what is called "substitutional alloys," meaning that the atoms of the two metals are randomly intermingled within a single atomic structure. But this can only happen if the two types of atoms are approximately the same size and have nearly the same electronegativity (propensity to attract electrons). By these criteria, known as the Hume-Rothery rules, cerium and aluminum are incompatible. Both cerium and aluminum form many useful alloys with other metals. But cerium atoms are 28% bigger than aluminum atoms, and have a significantly lower electronegativity. The two elements can form chemical compounds together, as well disordered mixtures called metallic glasses, but a cerium-aluminum alloy appeared to be off limits.

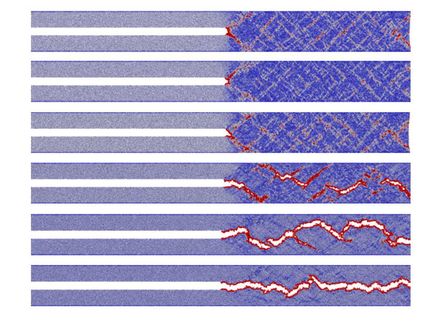

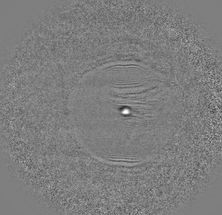

When high-pressure experiments on a sample of cerium-aluminum metallic glass began to show the properties of an alloy, the research team took notice. At 25 gigapascals of pressure the mismatched atoms overcame their differences and settled into a single crystal structure. "It wasn't totally unexpected ," says Mao. "Usually when you apply pressure in a case like this the bigger atom becomes smaller, but normally by just a few percent, not enough to allow an alloy to form."

In the case of cerium, however, pressure causes the atoms to shed some of their outermost electrons, making the electrons "delocalized". The delocalization of the electrons not only changes the electronegativity of the cerium atoms, it causes the atoms to collapse in volume by 15%. The net result is that both size and electronic structure are put in range that the cerium and aluminum atoms can comfortably nestle together, forming an alloy.

"This is a very important result in which two very different atoms can have the difference erased by the pressure effect," says Mao. "The second interesting thing is that it's quenchable, meaning that when we release the pressure the alloy persists. A lot of high pressure materials can be made, but once the pressure is reduced they go back to their original form. You cannot make anything useful from those materials. But this alloy is quenchable, so that creates possibilities."

The researchers are currently investigating the properties of the new alloy. One key finding is that after quenching, the delocalized electrons become localized again, suggesting that the alloy may retain some of cerium's magnetic properties. Rare earth elements such as cerium are components of the strongest known magnets. The new alloy could also have novel electronic and mechanical properties.

Mao notes that the success in producing this new alloy implies that other potentially useful combinations can be made under high pressure. "Aluminum is an archetypal material which has a small atoms and forms many alloys with other elements with small atoms," he says. "These other elements, such as magnesium, can probably also form alloys with cerium. So this result will open a lot of doors for new materials to study."

Original publication: Qiao-Shi Zenga et al. "Substitutional alloy of Ce and Al"; Proceedings of the National Academy of Sciences, February 24, 2009 vol. 106 no. 8 2515-2518

Most read news

Other news from the department science

Get the analytics and lab tech industry in your inbox

By submitting this form you agree that LUMITOS AG will send you the newsletter(s) selected above by email. Your data will not be passed on to third parties. Your data will be stored and processed in accordance with our data protection regulations. LUMITOS may contact you by email for the purpose of advertising or market and opinion surveys. You can revoke your consent at any time without giving reasons to LUMITOS AG, Ernst-Augustin-Str. 2, 12489 Berlin, Germany or by e-mail at revoke@lumitos.com with effect for the future. In addition, each email contains a link to unsubscribe from the corresponding newsletter.